IoT professionals and enthusiasts see how IoT tech impacts grandiose projects like smart city development and renewable energy. You feel these issues carry more gravity in the Earth’s recovery from climate change. However, fashion manufacturing is one of the most toxic sectors in the world.

It has been environmentally dishonest, with little traceable evidence of positive changes. IoT has the potential to bring fashion into a new era of accountability and consistency after years of greenwashing scandals and ineffective digital transformation. Sustainable fashion needs IoT as a catalyst.

Unraveling Fashion’s Need for Transparency

Visualizing how IoT impacts the fashion industry requires acknowledging how diverse and threatening the sector is. Fashion manufacturers produce 10 percent of the world’s greenhouse gas emissions in several environmentally concerning categories, including:

- Water consumption

- Overfarming and soil abuse through textile farming

- Ethical labor and working conditions issues

- Textile waste concerns and lack of recycling and circular economic practices

- Pollution from chemicals like dyes and microplastics

- Deforestation to create synthetic fabrics

- Reliance on fossil fuels for plastic-based products like hangers

Overconsumption has led many to flock to physical and online thrift stores instead of luxury or fast fashion retailers. However, there needs to be more than consumer-based action to solve systemic problems and the failure to execute digital transformation in fashion manufacturing. Additionally, fashion consumers want data from industrial IoT to prove corporations dedicate themselves to fighting climate change. Buyers also want to validate that their purchasing decisions are genuinely supporting ethical companies.

IoT can monitor and track each metric for fashion manufacturers. For example, it could automate publicizing material sourcing, product tracing, and carbon footprint transparency directly to consumers. IoT technology learns over time to deploy environmentally friendly business adjustments and offer data-based suggestions for decision-making.

Supply chains for fashion corporations are slowly changing because of myriad IoT devices, including sensors and cameras. Oversight is one feat, and conveying the results to business partners, stakeholders, and consumers is another. Most evaluated companies in the Fashion Transparency Index in 2023 underperformed. How can IoT oversee these diverse environmental targets and clarify their ecological progress?

Seeing IoT in Fashion Manufacturing in Action

The first step to transparency in fashion is using technology to be open about the data it collects. More consumers rely on e-commerce to access fashion. Fashion manufacturers could use these pathways to communicate with customers about environmental goals. Websites, social media platforms, and email marketing are a few. The fashion sector can send and publish environmental data from manufacturer IoT devices.

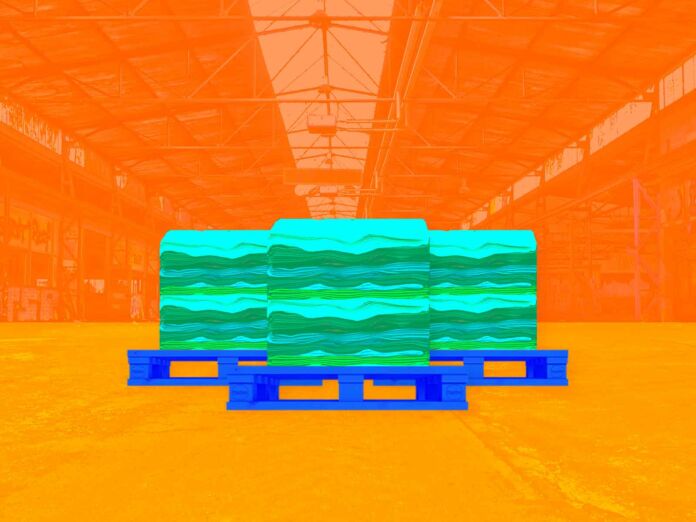

Make it publicly available and integrate it seamlessly with the top consumer digital channels. For example, a fashion manufacturer may employ IoT devices to manage warehouse inventory and waste. Their data shows unsold backlog sits on shelves, wasting real estate that requires resources to power. Automated garment tagging and cataloging assist manufacturers with minimizing overproduction, tracking lost and stolen products, and reducing textile waste from surplus.

It helps workers as well as consumers because a more agile manufacturing outfit saves energy through heightened productivity — a win for eco-friendly operations. IoT professionals can collate this data into transparent reports for stakeholders and consumers. This way, everyone knows the status of their inventory, the power wasted on unnecessary assets, and how they dispose of or repurpose old stores.

IoT enthusiasts must convince the fashion industry to leverage these numbers and insights to empower sustainable decisions, like incorporating a recycling program, executing better demand forecasting, or switching to renewable energy.

Recognizing the Impact of Two Disparate Sectors

Fashion and IoT feel like they are on opposite sides of the world, but bridging them forces innovation from a sustainable lens. Fashionable IoT advancements have surprising yet eco-conscious outcomes.

Nike created a smart shoe with automatic lacing, adjusting to the foot size to consider how athletes’ feet swell when exerted. Though this sounds like an unrelated, cool invention, it prevents wasteful returns and purchasing the same product multiple times — both consequences plague the fashion sector and are not ideal for sustainability.

Other brands like Alexander McQueen are partnering with technologies related to IoT, such as blockchain, to enhance transparency and traceability further. A case study explores how IoT and blockchain can prevent waste by eliminating counterfeiting and verifying the authenticity of material sourcing and transactions. These empowered technologies help procurement teams and supply chains make smart bidding decisions.

This data is essential to discuss publicly as scope three emissions and corporate responsibility become a hot topic among consumers. IoT has the means to solidify fashion manufacturers’ corporate sustainability intentions and commitments.

Embracing IoT for Authentically Green Fashion

Eco-friendly fashion became more of a trend in the last decade than what it should have started as — a mission for the planet’s greater good. Consumers and fashion corporations will have better relationships based on evidence-based reporting and transparency that sets an essential precedent. The way fashion manufacturers incorporate IoT into their ESG goals will inspire other industries to follow suit.

Tweet

Share

Share

- Sustainability

- ESG

- Asset Tracking

- Data Analytics

- Factory Automation

- Sustainability

- ESG

- Asset Tracking

- Data Analytics

- Factory Automation